|

| May 08, 2018 | Volume 14 Issue 17 |

Electrical/Electronic News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Intro to reed switches, magnets, magnetic fields

This brief introductory video on the DigiKey site offers tips for engineers designing with reed switches. Dr. Stephen Day, Ph.D. from Coto Technology gives a solid overview on reed switches -- complete with real-world application examples -- and a detailed explanation of how they react to magnetic fields.

This brief introductory video on the DigiKey site offers tips for engineers designing with reed switches. Dr. Stephen Day, Ph.D. from Coto Technology gives a solid overview on reed switches -- complete with real-world application examples -- and a detailed explanation of how they react to magnetic fields.

View the video.

Bi-color LEDs to light up your designs

Created with engineers and OEMs in mind, SpectraBright Series SMD RGB and Bi-Color LEDs from Visual Communi-cations Company (VCC) deliver efficiency, design flexibility, and control for devices in a range of industries, including mil-aero, automated guided vehicles, EV charging stations, industrial, telecom, IoT/smart home, and medical. These 50,000-hr bi-color and RGB options save money and space on the HMI, communicating two or three operating modes in a single component.

Created with engineers and OEMs in mind, SpectraBright Series SMD RGB and Bi-Color LEDs from Visual Communi-cations Company (VCC) deliver efficiency, design flexibility, and control for devices in a range of industries, including mil-aero, automated guided vehicles, EV charging stations, industrial, telecom, IoT/smart home, and medical. These 50,000-hr bi-color and RGB options save money and space on the HMI, communicating two or three operating modes in a single component.

Learn more.

All about slip rings: How they work and their uses

Rotary Systems has put together a really nice basic primer on slip rings -- electrical collectors that carry a current from a stationary wire into a rotating device. Common uses are for power, proximity switches, strain gauges, video, and Ethernet signal transmission. This introduction also covers how to specify, assembly types, and interface requirements. Rotary Systems also manufactures rotary unions for fluid applications.

Rotary Systems has put together a really nice basic primer on slip rings -- electrical collectors that carry a current from a stationary wire into a rotating device. Common uses are for power, proximity switches, strain gauges, video, and Ethernet signal transmission. This introduction also covers how to specify, assembly types, and interface requirements. Rotary Systems also manufactures rotary unions for fluid applications.

Read the overview.

Seifert thermoelectric coolers from AutomationDirect

Automation-Direct has added new high-quality and efficient stainless steel Seifert 340 BTU/H thermoelectric coolers with 120-V and 230-V power options. Thermoelectric coolers from Seifert use the Peltier Effect to create a temperature difference between the internal and ambient heat sinks, making internal air cooler while dissipating heat into the external environment. Fans assist the convective heat transfer from the heat sinks, which are optimized for maximum flow.

Automation-Direct has added new high-quality and efficient stainless steel Seifert 340 BTU/H thermoelectric coolers with 120-V and 230-V power options. Thermoelectric coolers from Seifert use the Peltier Effect to create a temperature difference between the internal and ambient heat sinks, making internal air cooler while dissipating heat into the external environment. Fans assist the convective heat transfer from the heat sinks, which are optimized for maximum flow.

Learn more.

EMI shielding honeycomb air vent panel design

Learn from the engineering experts at Parker how honeycomb air vent panels are used to help cool electronics with airflow while maintaining electromagnetic interference (EMI) shielding. Topics include: design features, cell size and thickness, platings and coatings, and a stacked design called OMNI CELL construction. These vents can be incorporated into enclosures where EMI radiation and susceptibility is a concern or where heat dissipation is necessary. Lots of good info.

Learn from the engineering experts at Parker how honeycomb air vent panels are used to help cool electronics with airflow while maintaining electromagnetic interference (EMI) shielding. Topics include: design features, cell size and thickness, platings and coatings, and a stacked design called OMNI CELL construction. These vents can be incorporated into enclosures where EMI radiation and susceptibility is a concern or where heat dissipation is necessary. Lots of good info.

Read the Parker blog.

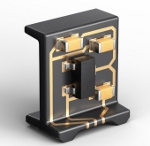

What is 3D-MID? Molded parts with integrated electronics from HARTING

3D-MID (three-dimensional mechatronic integrated devices) technology combines electronic and mechanical functionalities into a single, 3D component. It replaces the traditional printed circuit board and opens up many new opportunities. It takes injection-molded parts and uses laser-direct structuring to etch areas of conductor structures, which are filled with a copper plating process to create very precise electronic circuits. HARTING, the technology's developer, says it's "Like a PCB, but 3D." Tons of possibilities.

3D-MID (three-dimensional mechatronic integrated devices) technology combines electronic and mechanical functionalities into a single, 3D component. It replaces the traditional printed circuit board and opens up many new opportunities. It takes injection-molded parts and uses laser-direct structuring to etch areas of conductor structures, which are filled with a copper plating process to create very precise electronic circuits. HARTING, the technology's developer, says it's "Like a PCB, but 3D." Tons of possibilities.

View the video.

Loss-free conversion of 3D/CAD data

CT CoreTech-nologie has further developed its state-of-the-art CAD converter 3D_Evolution and is now introducing native interfaces for reading Solidedge and writing Nx and Solidworks files. It supports a wide range of formats such as Catia, Nx, Creo, Solidworks, Solidedge, Inventor, Step, and Jt, facilitating smooth interoperability between different systems and collaboration for engineers and designers in development environments with different CAD systems.

CT CoreTech-nologie has further developed its state-of-the-art CAD converter 3D_Evolution and is now introducing native interfaces for reading Solidedge and writing Nx and Solidworks files. It supports a wide range of formats such as Catia, Nx, Creo, Solidworks, Solidedge, Inventor, Step, and Jt, facilitating smooth interoperability between different systems and collaboration for engineers and designers in development environments with different CAD systems.

Learn more.

Top 5 reasons for solder joint failure

Solder joint reliability is often a pain point in the design of an electronic system. According to Tyler Ferris at ANSYS, a wide variety of factors affect joint reliability, and any one of them can drastically reduce joint lifetime. Properly identifying and mitigating potential causes during the design and manufacturing process can prevent costly and difficult-to-solve problems later in a product lifecycle.

Solder joint reliability is often a pain point in the design of an electronic system. According to Tyler Ferris at ANSYS, a wide variety of factors affect joint reliability, and any one of them can drastically reduce joint lifetime. Properly identifying and mitigating potential causes during the design and manufacturing process can prevent costly and difficult-to-solve problems later in a product lifecycle.

Read this informative ANSYS blog.

Advanced overtemp detection for EV battery packs

Littelfuse has introduced TTape, a ground-breaking over-temperature detection platform designed to transform the management of Li-ion battery systems. TTape helps vehicle systems monitor and manage premature cell aging effectively while reducing the risks associated with thermal runaway incidents. This solution is ideally suited for a wide range of applications, including automotive EV/HEVs, commercial vehicles, and energy storage systems.

Littelfuse has introduced TTape, a ground-breaking over-temperature detection platform designed to transform the management of Li-ion battery systems. TTape helps vehicle systems monitor and manage premature cell aging effectively while reducing the risks associated with thermal runaway incidents. This solution is ideally suited for a wide range of applications, including automotive EV/HEVs, commercial vehicles, and energy storage systems.

Learn more.

Benchtop ionizer for hands-free static elimination

EXAIR's Varistat Benchtop Ionizer is the latest solution for neutralizing static on charged surfaces in industrial settings. Using ionizing technology, the Varistat provides a hands-free solution that requires no compressed air. Easily mounted on benchtops or machines, it is manually adjustable and perfect for processes needing comprehensive coverage such as part assembly, web cleaning, printing, and more.

EXAIR's Varistat Benchtop Ionizer is the latest solution for neutralizing static on charged surfaces in industrial settings. Using ionizing technology, the Varistat provides a hands-free solution that requires no compressed air. Easily mounted on benchtops or machines, it is manually adjustable and perfect for processes needing comprehensive coverage such as part assembly, web cleaning, printing, and more.

Learn more.

LED light bars from AutomationDirect

Automation-Direct adds CCEA TRACK-ALPHA-PRO series LED light bars to expand their offering of industrial LED fixtures. Their rugged industrial-grade anodized aluminum construction makes TRACKALPHA-PRO ideal for use with medium to large-size industrial machine tools and for use in wet environments. These 120 VAC-rated, high-power LED lights provide intense, uniform lighting, with up to a 4,600-lumen output (100 lumens per watt). They come with a standard bracket mount that allows for angle adjustments. Optional TACLIP mounts (sold separately) provide for extra sturdy, vibration-resistant installations.

Automation-Direct adds CCEA TRACK-ALPHA-PRO series LED light bars to expand their offering of industrial LED fixtures. Their rugged industrial-grade anodized aluminum construction makes TRACKALPHA-PRO ideal for use with medium to large-size industrial machine tools and for use in wet environments. These 120 VAC-rated, high-power LED lights provide intense, uniform lighting, with up to a 4,600-lumen output (100 lumens per watt). They come with a standard bracket mount that allows for angle adjustments. Optional TACLIP mounts (sold separately) provide for extra sturdy, vibration-resistant installations.

Learn more.

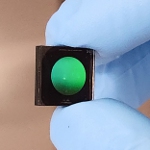

World's first metalens fisheye camera

2Pi Optics has begun commercial-ization of the first fisheye camera based on the company's proprietary metalens technology -- a breakthrough for electronics design engineers and product managers striving to miniaturize the tiny digital cameras used in advanced driver-assistance systems (ADAS), AR/VR, UAVs, robotics, and other industrial applications. This camera can operate at different wavelengths -- from visible, to near IR, to longer IR -- and is claimed to "outperform conventional refractive, wide-FOV optics in all areas: size, weight, performance, and cost."

2Pi Optics has begun commercial-ization of the first fisheye camera based on the company's proprietary metalens technology -- a breakthrough for electronics design engineers and product managers striving to miniaturize the tiny digital cameras used in advanced driver-assistance systems (ADAS), AR/VR, UAVs, robotics, and other industrial applications. This camera can operate at different wavelengths -- from visible, to near IR, to longer IR -- and is claimed to "outperform conventional refractive, wide-FOV optics in all areas: size, weight, performance, and cost."

Learn more.

Orbex offers two fiber optic rotary joint solutions

Orbex Group announces its 700 Series of fiber optic rotary joint (FORJ) assemblies, supporting either single or multi-mode operation ideal for high-speed digital transmission over long distances. Wavelengths available are 1,310 or 1,550 nm. Applications include marine cable reels, wind turbines, robotics, and high-def video transmission. Both options feature an outer diameter of 7 mm for installation in tight spaces. Construction includes a stainless steel housing.

Orbex Group announces its 700 Series of fiber optic rotary joint (FORJ) assemblies, supporting either single or multi-mode operation ideal for high-speed digital transmission over long distances. Wavelengths available are 1,310 or 1,550 nm. Applications include marine cable reels, wind turbines, robotics, and high-def video transmission. Both options feature an outer diameter of 7 mm for installation in tight spaces. Construction includes a stainless steel housing.

Learn more.

Mini tunnel magneto-resistance effect sensors

Littelfuse has released its highly anticipated 54100 and 54140 mini Tunnel Magneto-Resistance (TMR) effect sensors, offering unmatched sensitivity and power efficiency. The key differentiator is their remarkable sensitivity and 100x improvement in power efficiency compared to Hall Effect sensors. They are well suited for applications in position and limit sensing, RPM measurement, brushless DC motor commutation, and more in various markets including appliances, home and building automation, and the industrial sectors.

Littelfuse has released its highly anticipated 54100 and 54140 mini Tunnel Magneto-Resistance (TMR) effect sensors, offering unmatched sensitivity and power efficiency. The key differentiator is their remarkable sensitivity and 100x improvement in power efficiency compared to Hall Effect sensors. They are well suited for applications in position and limit sensing, RPM measurement, brushless DC motor commutation, and more in various markets including appliances, home and building automation, and the industrial sectors.

Learn more.

Panasonic solar and EV components available from Newark

Newark has added Panasonic Industry's solar inverters and EV charging system components to their power portfolio. These best-in-class products help designers meet the growing global demand for sustainable and renewable energy mobility systems. Offerings include film capacitors, power inductors, anti-surge thick film chip resistors, graphite thermal interface materials, power relays, capacitors, and wireless modules.

Newark has added Panasonic Industry's solar inverters and EV charging system components to their power portfolio. These best-in-class products help designers meet the growing global demand for sustainable and renewable energy mobility systems. Offerings include film capacitors, power inductors, anti-surge thick film chip resistors, graphite thermal interface materials, power relays, capacitors, and wireless modules.

Learn more.

Army research rejuvenates older zinc battery technology so it can compete with lithium-ion -- without exploding

Army scientists, with a team of researchers from the University of Maryland and the National Institute of Standards and Technology, have created a water-based zinc battery that is simultaneously powerful, rechargeable, and intrinsically safe.

The high-impact journal Nature Materials published a peer-reviewed paper based on this ground-breaking research April 16.

In prior achievements, these scientists invented a new class of water-based electrolytes that can work under extreme electrochemical conditions that tap water cannot, and have successfully applied it on different lithium-ion chemistries.

In this work, they adapted the electrolyte to a battery chemistry much cheaper but more problematic than lithium: zinc. They demonstrated that an aqueous zinc battery can satisfy the multi-facet goals of high energy, high safety, and low cost simultaneously.

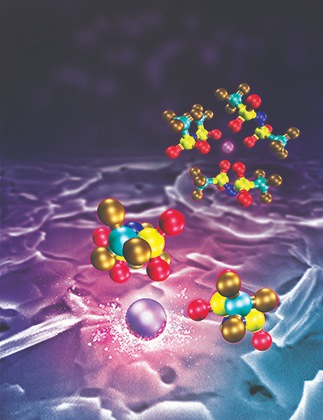

An artist's conception of a zinc ion that has been fully surrounded by anions in the super-concentrated electrolyte is trying to break out of the binding and deposit on zinc metal surface in a controlled and smooth manner. [Artwork by Eric Proctor]

The world's very first battery used zinc as an anode in 1799. In the following two centuries, many zinc-based batteries were commercialized, some of which are still on market. These batteries used to provide safe and reliable energy, although at moderate energy density, to satisfy our daily needs, but their presence in our lives has significantly shrunken since the emergence of lithium-ion batteries 28 years ago. Besides energy density, a major reason for the diminishing role of zinc batteries is the poor reversibility of the zinc chemistry in aqueous electrolytes. Non-rechargeable batteries already created a significant amount of landfill, imposing serious environmental burdens on industrialized societies.

"On the other hand, with the increasing presence of lithium-ion batteries in our lives, from portable electronics to electric vehicles, their safety raises more public concerns, from Tesla car fires to the global grounding of the entire Boeing 787 fleet," explained Dr. Kang Xu, who is an ARL fellow and team leader, and co-corresponding author of this paper. "The safety hazards of lithium-ion batteries are rooted in the highly flammable and toxic non-aqueous electrolytes used therein. The batteries of aqueous nature thus become attractive, if they can be made rechargeable with high energy densities. Zinc is a natural candidate."

The researchers said the new aqueous zinc battery could eventually be used not just in consumer electronics, but also in extreme conditions to improve the performance of safety-critical vehicles such as those used in aerospace, military, and deep-ocean environments.

As an example of the aqueous zinc battery's power and safety, Fei Wang, a jointly appointed postdoctoral associate at UMD's Clark School and ARL, and first author of the paper, cites the numerous battery fire incidents in cell phones, laptops, and electric cars highlighted in recent media coverage. The new aqueous zinc battery presented in this work could be the answer to the call for safe battery chemistry while still maintaining the comparable or even higher energy densities of conventional lithium-ion batteries.

"Water-based batteries could be crucial to preventing fires in electronics, but their energy storage and capacity have been limited -- until now. For the first time, we have a battery that could compete with the lithium-ion batteries in energy density, but without the risk of explosion or fire," Wang said.

This highly concentrated aqueous zinc battery also overcomes other disadvantages of conventional zinc batteries, such as the capacity to endure only limited recharging cycles, dendrite (tree-like structures of crystals) growth during usage and recharging, and sustained water consumption, resulting in the need to regularly replenish the batteries' electrolyte with water.

"Existing zinc batteries are safe and relatively inexpensive to produce, but they aren't perfect due to poor cycle life and low energy density. We overcome these challenges by using a water-in-salt electrolyte," says Chunsheng Wang, UMD professor of chemical and biomolecular engineering and corresponding author of the paper.

The research team says this battery technology advance lays the groundwork for further research, and they are hopeful for possible future commercialization.

"The significant discovery made in this work has touched the core problem of aqueous zinc batteries, and could impact other aqueous or non-aqueous multivalence cation chemistries that face similar challenges, such as magnesium and aluminum batteries", Xu said. "A much more difficult challenge is, of course, the reversibility of lithium metal, which faces similar but much more difficult challenges."

Resolution of lithium-metal deposition could unlock the "Holy Grail" of all batteries, which is an area these scientists are closely working on with the scientists at the Department of Energy, he said.

The research received funding support from the Department of Energy Advanced Research Projects Agency-Energy and the University of Maryland Center for Research in Extreme Batteries.

The authors acknowledged additional support from the University of Maryland NanoCenter.

Source: The U.S. Army Research Laboratory

Published May 2018

Rate this article

View our terms of use and privacy policy